Custom glass plates are a creative addition to your collection. There are different types of custom glass plates with several designs. Still, you can’t pick a plate based on its design, there are certain factors you should look out for. Today, we’ll explore these factors and give an in depth guide on choosing the right custom glass plate.

Key Factors to Consider

Before choosing a glass plate, there are certain things to consider. From its use to the production process, these factors determine the durability and value of your custom glass plates.

Purpose and Usage

The usefulness of your glass plates significantly impacts the selection process. For food service, you might want to ensure the techniques and materials used are food-safe. Consider factors like ability to handle heat changes, and durability before getting them.

Budget Considerations

Custom glass plates have different price ranges. So, it’s best to determine your budget before the process begins. Quality custom glass plates can seem pricey at the time of purchase but their durability and long lifespan makes their purchase worthwhile.

Quality Requirements

The quality of glass plates depends on several factors:

- Safety features and impact resistance

Glass is naturally sharp-edged and breaks easily. So, a glass plate should be beautiful, and safe. Practices like tempering or laminating, impact resistance and edge finishing, should be considered before getting a custom glass plate.

- Maintenance requirements and ease of cleaning

Every glass plate you get should be easy to clean. So, look out for smooth surfaces that can’t hold dirt, absence of small crystals and designs that are slightly resistant to everyday use and scratches.

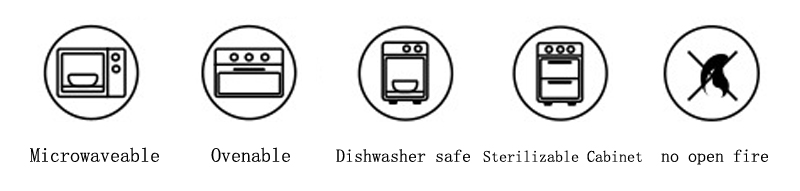

- Thermal performance and durability

Your ideal custom glass plate should be able to manage sudden temperature changes and chemical corrosion without breaking. This glass should have longevity and even outlive its owners without breaking down.

Timeline Needs

Custom glass production requires careful planning and execution. The artist and client should consider:

- Design approval process

- Material procurement

- Manufacturing and customization

- Quality control inspections

Common Customization Mistakes to Avoid

A well designed custom glass plate can elevate every space. Yet, a poor design is very disappointing. By avoiding these mistakes, you’ll get eye-catching pieces that meet your needs and modernize your space.

Design Pitfalls

When personalizing glass plates, it’s easy to overlook some practices. Unfortunately, these elements will affect the quality of your glass plate. Knowing these mistakes can help you get the best results.

When customizing glass plates, avoid:

- Uneven etched areas

When engraving or etching on the glass ware, avoid large areas. Etching can be difficult if done on a large surface. It will make your work uneven; ultimately losing its beauty.

- Overlooking pattern connectivity in designs

In the production of custom glass plates, haste will not favour you. It’s important that all patterns are connected and flow smoothly. Disconnected patterns can give your glass work a very unbalanced appearance.

- Using inappropriate decorative techniques for food-contact surfaces

The wrong decorative techniques for glasses used to serve food will affect the safety measures used. It is important you use only food-friendly techniques during the “finishing” stage of your production.

Material Selection Errors

Choose materials carefully to prevent:

- Incompatibility issues between different types of glass

- Poor ability to manage sudden heat changes

- Poor strength for the intended purpose

Size Miscalculations

Consider these aspects when determining size:

- Proper proportions for intended use

What is the value of a beautiful plate if it can’t serve its primary purpose. So, it’s best you take the measurements of the edible it will hold before you begin the design work.

- Storage space requirements

Get the right storage space and how it will be stored. Safe storage will reduce cracking and maintain the longevity of the glass plate.

- Similarity or Compatibility with existing tableware

Budget Oversights

Avoid common budget-related mistakes by:

- Deliberately keeping maintenance costs

- Compare durability to the initial costs

- Including costs for any additional service or storage.

Final Words

Your custom glass plate project largely depends on careful planning and attention to detail. So, every ‘t’ must be crossed and your ‘i’ should be well dotted. This will help you achieve your goal or even exceed your expectations. Your budget should focus on quality and safety, not cost and design alone.

If you have any questions or need to custom dinnerware service, please contact our Email:info@gcporcelain.com for the most thoughtful support!

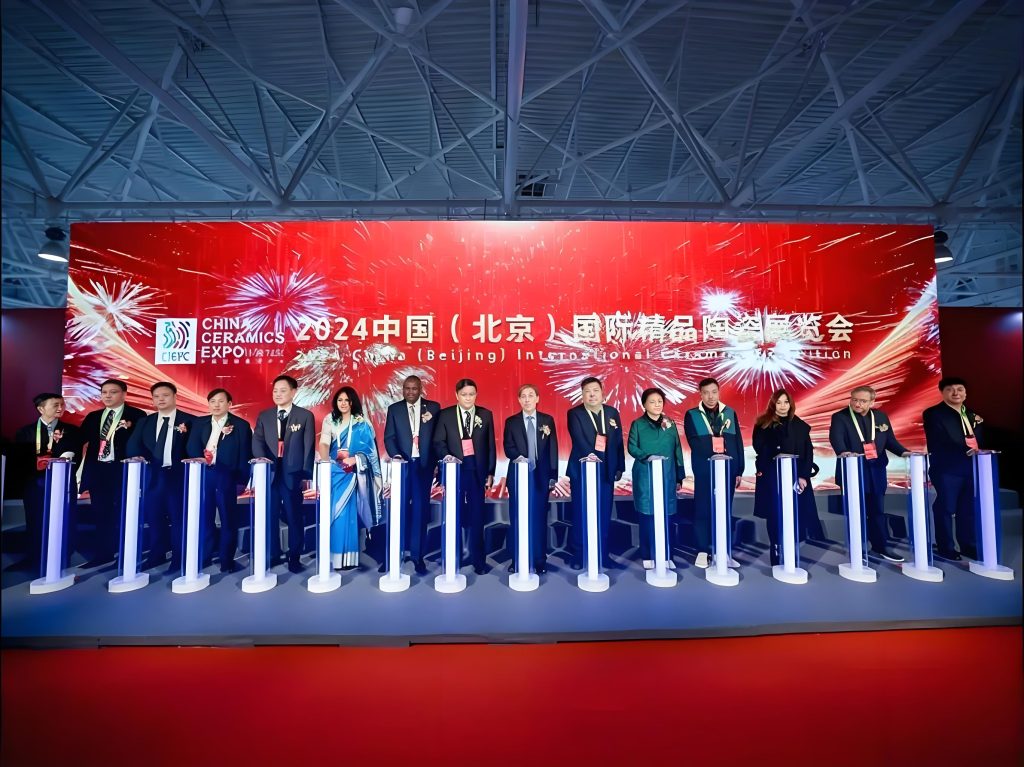

Welcome To Our Custom Glass Plate Production Line Factory!

Frequently Asked Questions