The Custom Glass Plate Creation Process

The production of custom glass plates is a blend of technology, creativity and traditional craftsmanship. It requires diligence, precision and a strong artistic mind. In this article, we will explore the production process from the ideation stage to the final products.

Design Phase

The first step in creating a mind-blowing custom glass plate is the design phase. This is where the ideas, visions and expectations of the client are put on paper. The appropriate resources are chosen and a guiding sample or illustration is generated.

- Initial Consultation

Here, the artist and client meet to discuss the project. The client provides necessary information like their ideas about the project, preferred materials and design style. During this discussion, the artist gives the client several options and a potential design style that may match the clients’ needs.

The consultation is where the plans, strategy and potential result of the project are discussed.

- Design Concepts

After the consultation, the artist brings the clients ideas to reality. They might opt for the traditional paper sketches, provide 3D images or design a mock-up of the clients desire. This stage gives the client a visual representation of the project and its potential result. Key elements like colours, patterns, and design style will be added to the images and mockups used at this stage.

- Proofing Process

This is the stage of potential results and refinement. There is a constant flow of communication between the client and artist at this stage. The mockups, images and sketches are sent to the client, and the artist waits for the necessary feedback.The feedback may be a request to change a key element or fine-tune the design.

The artist also informs the client that the 3D renditions and mockups will be similar to the final product but will not have the same quality.

- Design Approval

This is the last stage of the design phase where agreements are finalized. After all necessary adjustments have been made, the client approves the design which will act as a template during the production process.

Manufacturing Process

This is the creation stage where the result of the design phase is executed. Here, craftsmanship and skill are in high demand.

- Material Selection

The primary resource for production is the glass. The type of glass you use, strongly influences the design. Specially manufactured fusible glass is ideal for a fused glass work.

- Design Transfer

After all materials have been chosen, the design is imprinted on the glass. The design may be engraved, sandblasted or even lasered on the glass plate. Tiny coloured glass, sand or other abrasives might be used to create the desired design.

Customization Technique

There are different customization methods in the glass making industry. Each method gives a different result. We’ll explore the common customization methods in this section.

- Fusing

Arranged glass pieces are placed in a kiln which is a heated chamber or oven used to dry or burn anything. The glass in the kiln is subjected to high temperatures about 1475°F or 801°C. The high temperature causes the glass to melt and fuse together.

- Slumping

After fusing, the melted glass is placed in a mold and exposed to more heat. The heat and mold gives the glass its new form.

- Painting

Some glass works will require special glass painting before they are exposed to fire.

- Cold working

This might include cutting the piece on a tile saw, evening out edges using a wet belt sander, or sandblasting to create texture or remove blemishes.

- Quality Control

All through the manufacturing process, quality control is important. The glass is carefully cleaned before firing to prevent any imperfections or blemishes in the final product. After each firing, the piece is inspected for any flaws or small crystals stuck in the glass.

Finishing Touches

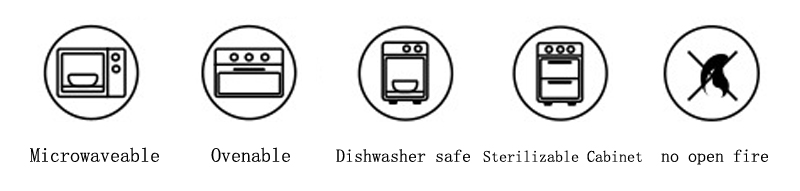

After the final firing and molding, polishing and safety checks are done by cold working. Safety checks like edges polishing, necessary coatings or holes will be added to the glass work. Additional edible-friendly materials and techniques will be used to make the glass plate suitable for eating, storing or microwaving.

After every process has been duly followed, the artist finishes by signing the piece; making it a unique artwork.

Final Words

The custom glass plate creation process is very delicate and technical. Each step is carefully executed to produce a unique, high-quality piece of functional art that meets the client’s specifications and exceeds their expectations.

If you have any questions or need to custom dinnerware service, please contact our Email:info@gcporcelain.com for the most thoughtful support!

Welcome To Our Custom Glass Plate Production Line Factory!

Frequently Asked Questions